Adding Bar Code Components

The are many bar code symbologies supported by this product, both 1D and 2D.

What is important about bar code design is the dpi (resolution) of the printer. Whether the printer is a bar code printer, laser printer or ink jet printer, the resolution is a very important factor. The resolution determines the thickness of the lines in a linear 1D barcode and the size of an element in a 2D barcode.

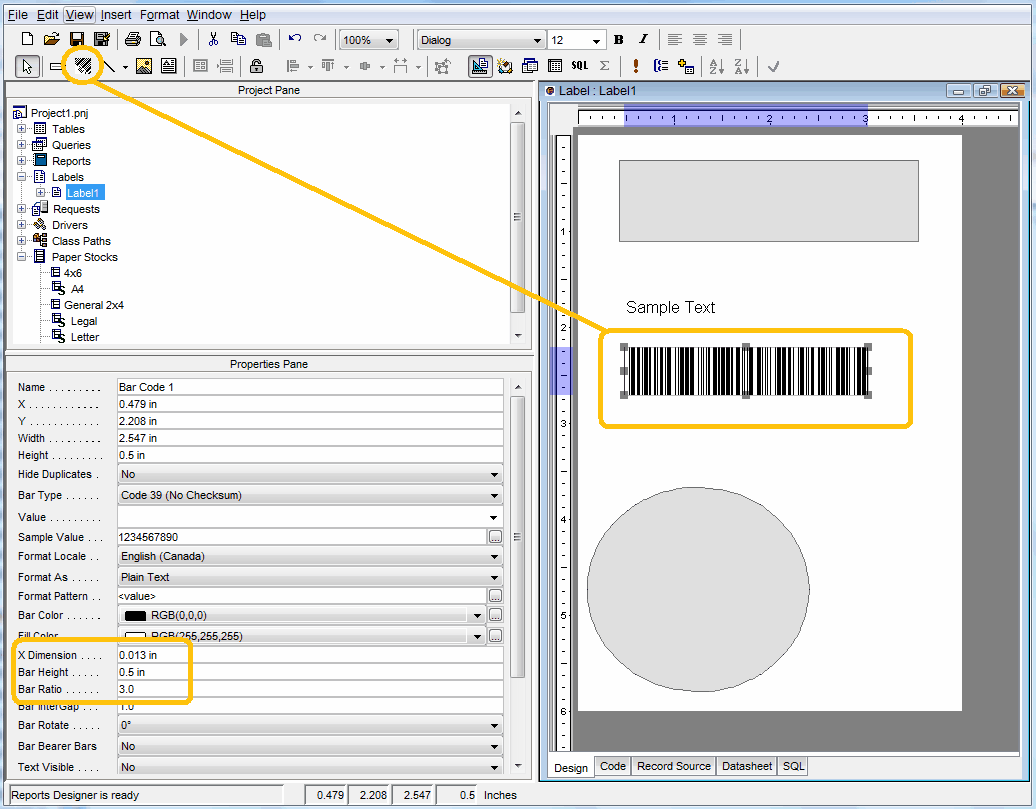

When you are working with 1D barcodes, the documentation describing the label you wish to produce will normally state the bar code symbology: Code 39, Interleave 2 of 5, UPC, etc. It will normally go on to state you need a certain X Dimension stated in mils: 10mil, 13mil, 15mil or 20mil or it states the number of pixels (dots) at a specific resolution (152, 200, 300, 400, or 600 dpi). It should also specify the Bar Height. For some 1D barcodes, it will also specify the ratio of the narrowest bar to the widest bar, termed the Bar Ratio. If these properties apply to a particular bar code symbology they will be displayed in the Properties Pane for that component as show below.

So what does the resolution of the printer have to do this bar codes? The issue is with the X Dimension. The table below describes the X Dimensions a printer can accurately reproduce at various resolutions. You will note that at certain resolutions the printer can not properly print all X Dimensions accurately, so the printer will automatically select the nearest X Dimension that it can print accurately. If it failed to do this, the bar code would fail to scan in the worst case or the scan quality would drop below acceptable norms. A label specification document will normally include a section on the acceptable scan quality of the bar codes required on the label.

X Dimension in pixels (dots) |

6 dots per millimeter 152.4 dots per inch |

8 dots per millimeter 203.2 dots per inch |

12 dots per millimeter 304.8 dots per inch |

1 |

1/152.4 = 0.0065 inches or 7 mils |

0.0049 inches or 5 mils |

0.0032 or 3 mils |

2 |

2/152.4 = 0.0131 inches or 13 mils |

0.0098 inches or 10 mils |

0.0065 or 7 mils |

3 |

3/152.4 = 0.0196 inches or 20 mils |

0.0147 inches or 14 mils |

0.0098 or 10 mils |

4 |

4/152.4 = 0.0262 inches or 26 mils |

0.0196 inches or 20 mils |

0.0131 or 13 mils |

5 |

5/152.4 = 0.0328 inches or 33 mils |

0.0246 inches or 24 mils |

0.0164 or 16 mils |

6 |

|

|

0.0196 or 20 mils |

7 |

|

|

0.0229 or 23 mils |

8 |

|

|

0.0262 or 26 mils |

X Dimension in pixels (dots) |

16 dots per millimeter 406.4 dots per inch |

24 dots per millimeter 609.4 dots per inch |

48 dots per millimeter 1219.2 dots per inch |

1 |

0.0024 |

0.0016 |

0.0008 |

2 |

0.0049 |

0.0032 |

0.0016 |

3 |

0.0073 |

0.0049 |

0.00024 |

4 |

0.0098 or 10 mils |

0.0065 |

0.0032 |

5 |

0.0123 or 12 mils |

0.0082 |

0.0041 |

6 |

0.0147 or 15 mils |

0.0098 or 10 mils |

0.0049 |

7 |

0.0172 |

0.0114 |

0.0065 |

8 |

0.0196 or 20 mils |

0.0131 or 13 mils |

0.0073 |

9 |

0.0221 |

0.0147 or 15 mils |

0.0073 |

10 |

0.0246 or 25 mils |

0.0165 or 16 mils |

0.0082 |

11 |

0.0270 |

0.0180 |

0.0090 |

12 |

|

0.0196 or 20 mils |

0.0098 or 10 mils |

13 |

|

0.0213 |

0.0106 |

14 |

|

0.0229 |

0.0114 |

15 |

|

0.0246 |

0.0123 |

16 |

|

|

0.0131 or 13 mils |

17 |

|

|

0.0139 |

18 |

|

|

0.0147 or 15 mils |

19 |

|

|

|

... |

|

|

|

25 |

|

|

0.0205 or 20 mils |

|

|

|

|

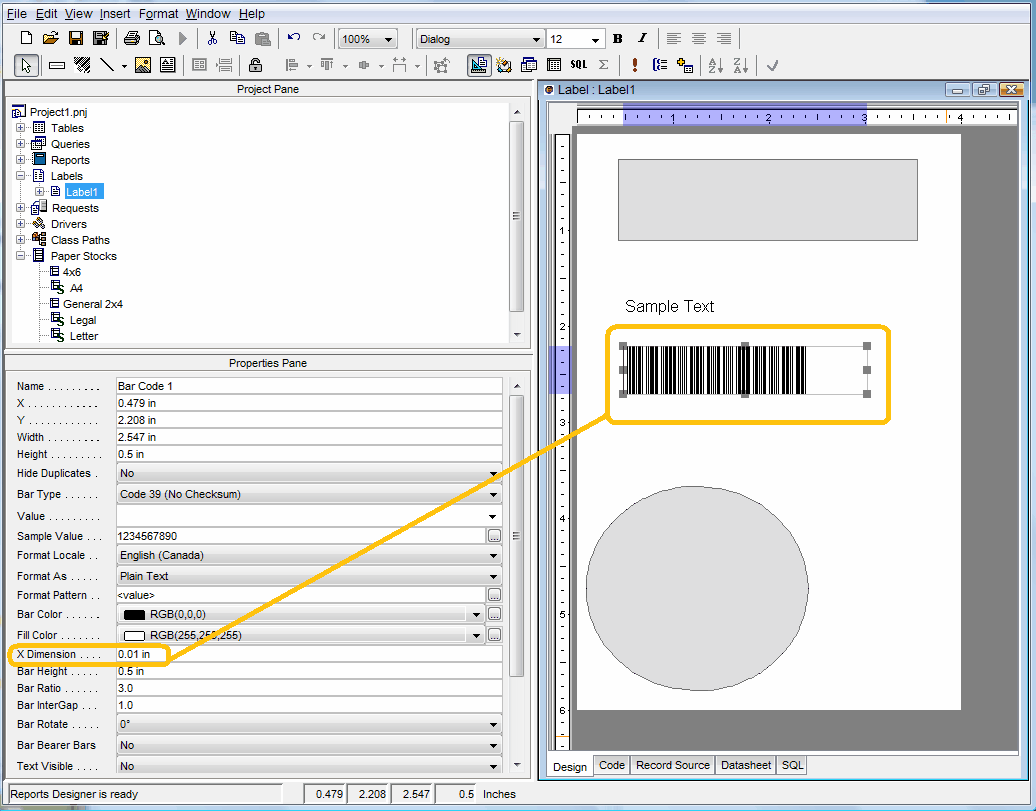

The formula is the X Dimension in pixels (dots) divided by the resolution of the printer in dots per inch. By doing this for a range of X Dimensions, the possible values for the X Dimension which the printer can accurately print a bar code can be determined. Basically, an X Dimension of 10 mils (0.010 inches) or 20 mils (0.020 inches) can be reproduced on all printers. However, an X Dimension of 13 mils (0.013 inches) can only be accurately reproduced on 152.4, 304.8, 609.4 or 1219.2 printer and not at 203.2 nor 406.4. In the later case, the printer will produce the bar code with the nearest possible X Dimension to 13 mils which for a printer with 203.2 dots per inch is 14 mils and for a printer with 406.4 dots per inch will be 12 mils.

The affect of the printer changing the X Dimension will result in the bar code printing either wider (larger) or narrower (smaller) then displayed in the design view. So it is important to do test prints to see if this is happening.

For compatibility reasons, change the X Dimension for 0.013 mils (0.013 inches) to 10 mils (0.01 inches) as shown below:

Good time to save the project.