PEERNET Intermec IPL Printer

The PEERNET Intermec IPL Printer allows for the production of labels on most Intermec model printers. Label formats are generated and printed in a WYSIWYG format, allowing access to the printers' built-in typefaces, integrated bar code support, and many other printer-specific features.

The PEERNET Intermec IPL Printer will use the Intermec printers' native command syntax to generate label formats where possible. Those features that are not supported by your particular Intermec printer will be simulated by rendering them as graphics.

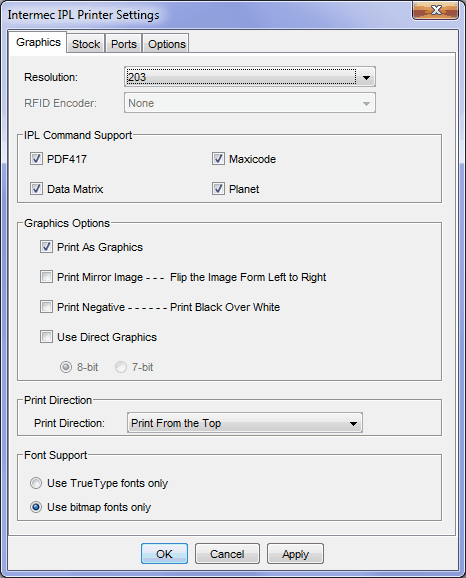

The configuration dialog for this printer contains 4 tabs that allow you to configure various aspects of the printer.

Configuration Options - Graphics Settings

Intermec IPL Configuration Dialog - Graphics Options

Resolution

This setting controls the resolution of the output at the physical printer in dots per inch (dpi). You can currently choose from 4 settings: 150 dpi, 203 dpi, 300 dpi, 400 dpi or 403 dpi. The default setting is 300 dpi.

RFID Encoder

This settings allows you to specify the type of RFID encoder that is present in your printer. The default setting is None, as not all Intermec printers contain an integrated RFID encoder. Consult your printers' documentation for details on the RFID encoder included with your printer (if any).

IPL Command Support

This section allows for specification of items that may not necessarily be natively supported on all Intermec printer models. Items that are selected are assumed to be natively supported by the printer, and native commands will be generated to print them. If one or more of these items are not natively supported by your Intermec printer, unselecting them will cause the PEERNET Reports Designer to simulate them by rendering them as graphic images.

The following items are made available:

•Bar Codes: PDF417, Maxicode, DataMatrix, Planet

Graphics Options

These options control how graphics are treated on the label format, and how the overall label format is generated.

Print As Graphics - when selected, this option causes the entire label format to be treated as a graphic or a series of graphic images, and essentially bypasses all native support for any item, including text, bar codes, lines and other natively supported elements.

Print Mirror Image - when selected, this option will attempt to print the label as a mirror image of what is currently displayed in the design view by flipping the elements of the label from left to right.

Print Negative - when selected, this option will attempt to print the label as a negative image, with all white portions printed black and all black portions printed white.

Print Direction

This section controls where the top of form on the label is located relative to the direction of printing. The default for this setting is Print From the Top.

Font Support

Many Intermec printers that support the IPL command set include native support for both bitmap fonts and True Type fonts. The options presented here allow you to select which type of font to use.

Use True Type fonts only - when this option is selected, PEERNET Reports Designer will create and download True Type fonts to the printer to render any text that is on a label or report design. True Type fonts allow for proper scaling, resulting in potentially fewer fonts being downloaded to the printer. This can have a direct impact on speed (especially in large batches or in label or report designs that use multiple sizes of a single font) and the amount of data transmitted to the printer.

Use bitmap fonts only - when selected, this option will instruct PEERNET Reports Designer to create and download bitmap fonts to the printer to render any text that is on a label or report design. Using bitmap fonts on labels or reports with large amounts of text typically results in a larger amount of data transmitted to the printer and slower printing (especially in large batches).

We highly recommend using True Type fonts for any label or report designs if possible. Using True Type fonts will generate smaller label and report layouts when they are generated for the printer, and they scale much better than bitmap fonts (which actually do not scale). |

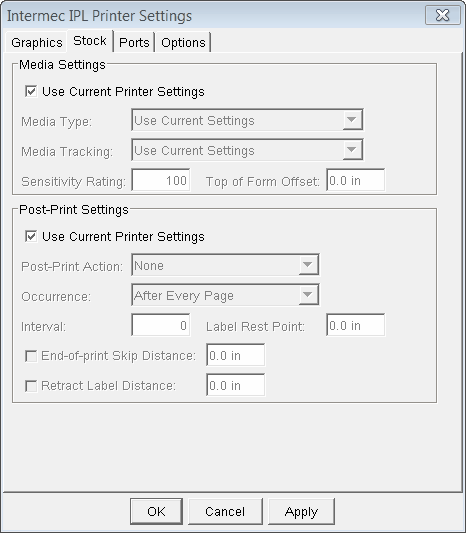

Configuration Options - Stock Settings

Stock Options tab of the Intermec IPL Configuration Dialog

Media Settings

These options allow you to control the specifics about the stock that you are using in your printer and how the printer functions to actually print data on the stock.

If the Use Current Printer Settings checkbox is selected, all other options in the Media Settings group are disabled and any customizations for these settings are taken from the printer itself. This allows you to make changes to these settings at the printer console itself without having to change these settings here for several different label formats that are going to the same printer.

Media Type - this allows you to specify what kind of media to use, either Direct Thermal or Thermal Transfer. The Direct Thermal setting indicates that the printer will not use a ribbon to print; in this case, the stock used must be heat sensitive. The Thermal Transfer setting results in the use of a ribbon to print. Consult your printers' documentation for more details regarding which media type is the most appropriate for your printer.

Media Tracking - this setting allows you to configure how the labels are arranged on the stock that you are currently using. Continuous is generally used for stock where the labels are arranged without any kind of physical separator between individual labels. Labels With Gaps is used for those stocks where the labels are arranged with physical gaps between them. Labels With Marks is typically used when the labels on the stock are arranged with some sort of reflective mark used to separate individual labels.

Sensitivity Rating - controls the sensitivity of the print head relative to the media type. Valid values can be in the range of 100 - 999. The default values for this option vary depending on the selected media type and the printer model, as shown in the table below.

Default Sensitivity Ratings by Printer Model

Printer Model |

Direct Thermal |

Thermal Transfer |

Intermec 3240 |

420 |

567 |

Intermec 3400A, 3400B |

420 |

567 |

Intermec 3400C, 3400D |

470 |

567 |

Intermec 3400e |

470 (152 - 203 dpi) 720 (300 dpi) |

567 |

Intermec 3440 |

470 |

567 |

Intermec 3600 |

420 |

567 |

Intermec 4100 |

420 |

567 |

Intermec 4400 |

420 |

567 |

Intermec 44X0 |

470 (152 - 203 dpi) 720 (300 dpi) |

567 |

Intermec 4X30 |

N/A |

N/A |

Intermec 7421, PC41 |

180 |

567 |

Intermec F4, PD/PF/PM/PX Series |

420 |

567 |

Intermec PB50 |

180 (normal media) 103 (liner-less media) |

N/A |

Top of Form Offset - this option allows you to change the horizontal adjustment of the point where printing will begin on the label. This setting is set to 0 by default, resulting in no adjustment to the horizontal start position.

Post-Print Settings

All post-print options allow the user to specify actions to take place after a label or several labels is/are printed. Many of the options available here rely on specific functionality of the printer (such as the presence of a cutter). In these cases, it is necessary to consult your printers' documentation to determine whether a specific post-print action is valid for your particular printer.

Print Mode - specifies the action to take after a particular number of labels has been printed (by default, after each label is printed). The default setting is None, which means that no action is taken after a label is printed. Available actions here are None and Cut.

When Cut is specified, the printer will print the label and perform a physical cut, provided the printer is equipped with a cutter. If there is no cutter present, this command is ignored, as well as any associated specification for the occurrence of the cut action.

Occurrence - allows the user to change when the specified print mode is done.

Interval - Used in conjunction with the 'After Specified Interval' setting of the Occurrence drop-down, allows the user to specify the number of labels to print before the selected post-print action is performed. This value is independent of the number of copies to print. This setting has a range of 1 to 9999 with a default value of 1, and is ignored completely if the value for Occurrence is anything other than 'After Specified Interval'.

Label Rest Point - this option allows the user to indicate a vertical adjustment of the point where printing will begin on the next label. Essentially, this setting controls the distance that the printed label will be presented to the user so that it can be torn off, cut, or stripped from the label backing.

End-of-Print Skip Distance - specifies an extra distance to advance the label stock after each printed label. It is used mainly to add a simulated label gap between label images when printing on continuous label stock.

Retract Label Distance - specifies a distance to rewind the label stock after printing a label. This option is often used to reset the stock to the top of the next label when using the label rest point to present a label for cutting, tear off or removal from the label backing. It is recommended that this setting NOT be used unless you have also specified a non-zero value for the label rest point; doing so in this case would causing labels to print with a jerky motion, substantially slowing down the printing of large label batches.

|

Minimum Value (in) |

Minimum Value (mm) |

Maximum Value (in) |

Maximum Value (mm) |

Top of Form Offset |

-0.05 |

-1.3 |

19.70 |

500.5 |

End of Print Skip Distance |

0.0 |

0.0 |

49.26 |

1251.1 |

Label Retract Distance |

0.0 |

0.0 |

1.96 |

49.9 |

Label Rest Point |

-0.15 |

-3.8 |

0.15 |

3.8 |

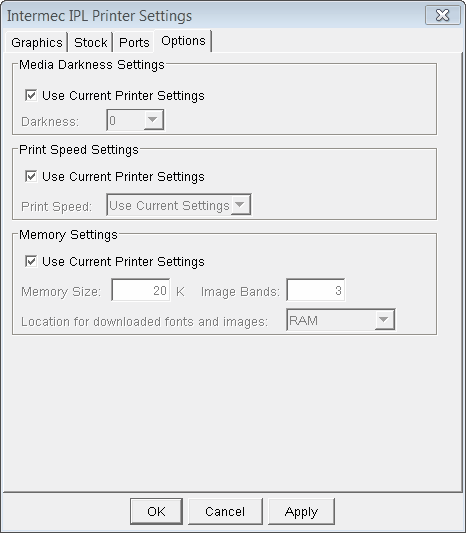

Configuration Options - Options Settings

Options tab of the Intermec IPL Configuration Dialog

These settings allow the user to exert fine-grain control of several Intermec printer options, including print speeds, print head function, post-print actions and printer memory settings.

Media Darkness Settings

These settings allow the user to make adjustments to the darkness setting of the print head.

If the Use Current Printer Settings checkbox is selected, all other options in the Media Darkness Settings group are disabled and any customizations for these settings are taken from the printer itself. This allows you to make changes to these settings at the printer console itself without having to change these settings here for several different label formats that are going to the same printer.

Darkness - specifies the amount of heat applied by the print head to the media, which has the effect of lightening or darkening the print contrast. The default specifies a darkness value of 0.

Print Speed Settings

The options presented here allow you to make adjustments to the various speed settings available on Intermec printers.

If the Use Current Printer Settings checkbox is selected, all other options in the Print Speed Settings group are disabled and any customizations for these settings are taken from the printer itself. This allows you to make changes to these settings at the printer console itself without having to change these settings here for several different label formats that are going to the same printer.

Print Speed - specifies the rate at which labels are printed. The default is to use the current printer settings; this has the same effect as selecting the 'Use Current Printer Settings' checkbox in that the print speed is not sent to the printer and the print speed setting is taken from the printer itself.

|

Minimum Speed |

Maximum Speed |

||

|

Imperial (in/sec) |

Metric (mm/sec) |

Imperial (in/sec) |

Metric (mm/sec) |

Print Speed |

2 |

50.8 |

10 |

254.0 |

Memory Settings

Memory Size

Intermec printers allow the users a certain amount of control over where fonts and image information can be downloaded and how much of the printers' memory can be used for such purposes. Memory capacity varies by printer model, as does expansion capability. Older Intermec printer models only allow a portion of the available memory to be available for downloaded images and fonts, while newer models allow all available memory to be used in such a fashion.

This setting allows you to specify how much memory is available in the printer, in kilobytes. It is recommended that this option be set to the maximum size available, including any memory upgrades that have been installed. Consult your printers' user guide for more information on the available values for this setting.

Image Bands

The Image Bands setting allows the user to fine-tune how much memory the printer uses when transferring information about the label format from the printers' memory to the print head. All label format information is rendered as dot patters in the printers' image buffer, and then transmitted to the print head for printing in the form a "bands", each band corresponding to a one-inch tall slice of the label to be printed. The number of bands specified here should be enough to hold a label one inch taller than the height of the label being printed. Since Intermec printers automatically requests the appropriate number of image bands for the current label format, it is normally not necessary to change this setting. The default value for this setting for all Intermec printer models is 3; other valid values vary by printer model, and are presented in the table below:

Printer Model |

Minimum Value |

Maximum Value |

3240 |

2 |

5 if the printer has 128K of RAM 7 if the printer has expanded RAM |

3400 |

2 |

6 if the printer has 32K of RAM 12 if the printer has expanded RAM |

3400e |

2 |

20 at 200dpi if the printer has 1MB of RAM 9 at 400dpi if the printer has 1MB of RAM 20 at 400dpi if the printer has expanded RAM |

3440 |

2 |

9 if the printer has 1MB of RAM 20 if the printer has expanded RAM |

3600 |

2 |

13 if the printer has 128K of RAM 25 if the printer has expanded RAM |

4100 |

2 |

6 if the printer has 32K of RAM 12 if the printer has expanded RAM |

4400 |

2 |

10 if the printer has 512K of RAM |

4420 |

2 |

20 if the printer has 1MB of RAM |

4440 |

2 |

9 if the printer has 1MB of RAM 20 if the printer has expanded RAM |

7421, PC41 |

2 |

12 if the printer has 512K of RAM |

Limitations

1. The following bar codes are not fully supported by Intermec printers, and will always be simulated as graphics when printed:

•All 4-State bar codes

•Anker

•Planet

•Facing Identification Mark (FIM)

•Plessey

•MSI

•Industrial 2 of 5

•Standard 2 of 5

•SCC-14

•SSCC-18

•Matrix 2 of 5

2. The following bar codes are simulated as graphics only under certain conditions:

•PDF417

PEERNET Reports Designer will make every attempt to generate this bar code using native command syntax; however, this bar code will be simulated as a graphic if any of the following conditions are met:

othe aspect ratio is out of range, or

othe ECC level specified is out of range

•Maxicode

This bar code will be simulated as a graphic if the data is encoded in any mode other than mode 2 or mode 3.

3. The following graphic items are not natively supported by the Intermec command syntax, and are simulated as graphics:

•Arcs

•Ellipses and ovals (including circles)

•Rounded rectangles

•Polygons

•Diagonal lines

•White lines or white-filled rectangles

4. PEERNET Reports Designer does not make use of any fonts that are built-in to the Intermec printer, including any supplied internal bitmapped fonts, smooth fonts, or scalable fonts. All fonts used in labels created with PEERNET Reports Designer are generated as bitmapped fonts on the fly, and are downloaded to the printer on an as-needed basis.

5. When the Print As Graphics option is enabled, label size will be a determining factor into whether or not the printer will actually print the resulting image. Larger labels (4"x6" or larger) will not render when the entire label is printed as a graphic. This option should be reserved for smaller label sizes only.

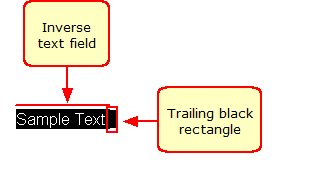

6. Printing inverse text (white text on a black background) through the Intermec IPL built-in thermal printer that is included in PEERNET Reports Designer can result in a small black rectangle trailing the text, as illustrated below:

This can be corrected by any of the following methods:

•Make the text field slightly larger in the Design View and re-printing the label, or

•Printing the entire label as an image by enabling the Print as Graphics option on the Graphics tab of the Intermec IPL Configuration Dialog.